Good evening,

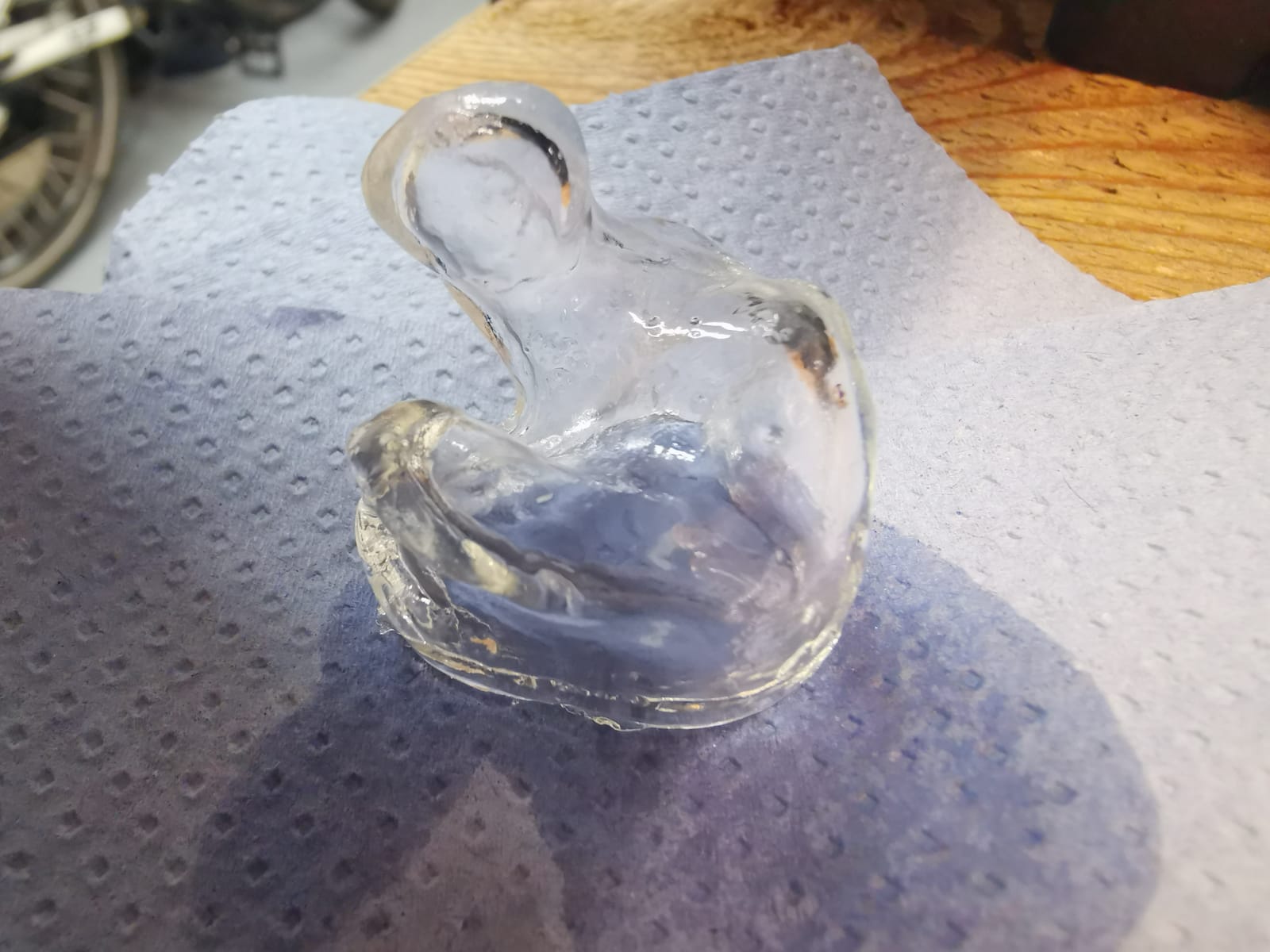

I just made my first shells and this is how they came out. They are between 1.2mm and 1.8mm. I am pleased with the results! I think? I will elaborate.

I tried a pair to see how they fit. Very good; at first. Total seal. Amazed that the process worked. But if I move my mouth a bit or look around etc, they loosen ever so slightly. Not enough to break the seal; far from, but enough that I can tell that the seal is not as good as first insertion. Quickly corrected by a gentle press on the shell. Its still sealed after I move my jaw or whatever, just not 100% perfect. Perhaps only 80%.

Is this normal? If so, fine. If not, should I start again?

I had the impressions done professionally, with a somewhat closed jaw. Just biting my tongue gently. My use case is at a PC so my jaw is basically always closed like that so I wanted maximum comfort and not an open mouth impression.

Should I look to getting a partially open jaw impression done instead? Will this offer worse comfort while my jaw is closed?

Should the final lacquer coats be sufficient to offer a slightly improved seal if I move? How much thickness does 1 coat add? Does anyone ever do multiple?

I dipped my impressions wax just 1 time before the casting process.

Any guidance appreciated. Here are some pictures of tonight's progress. Straight out of the UV lamp then cleaned, nothing else done: